Welcome to our AKSH Engineering

Introduction to Spray Drying

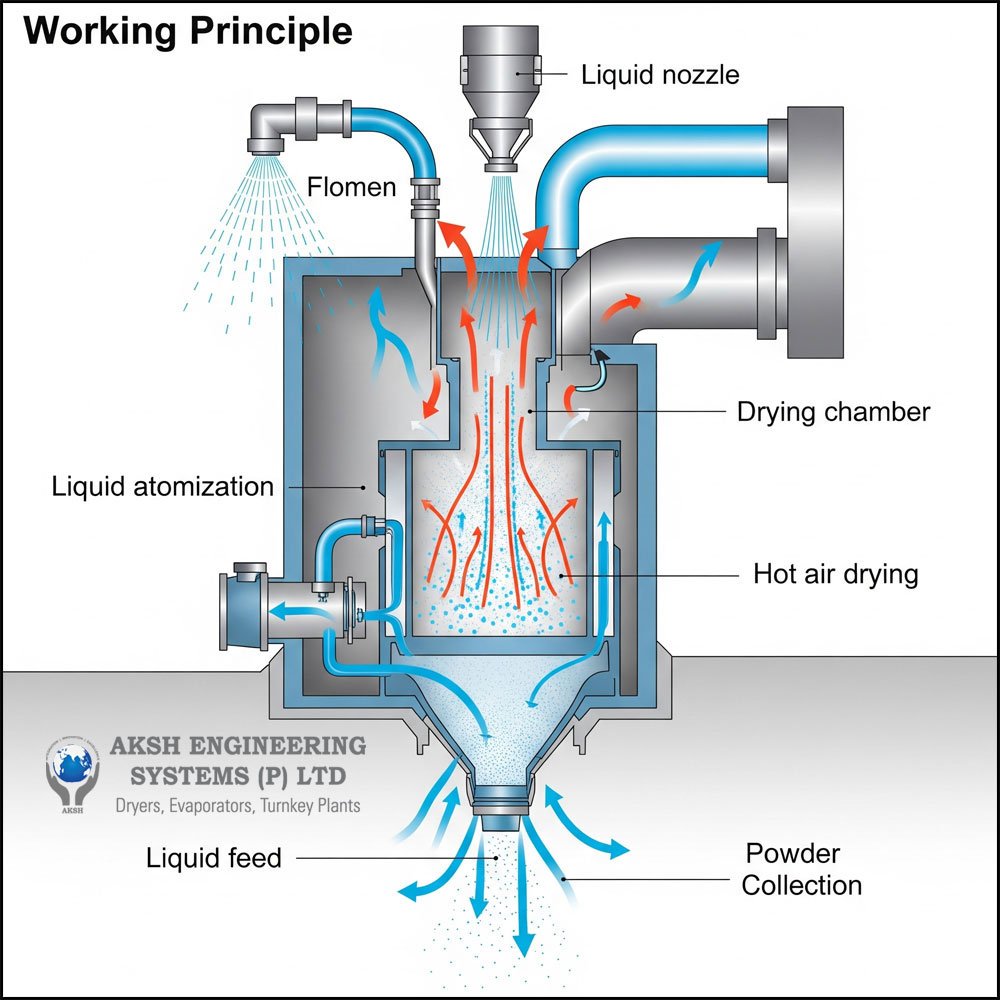

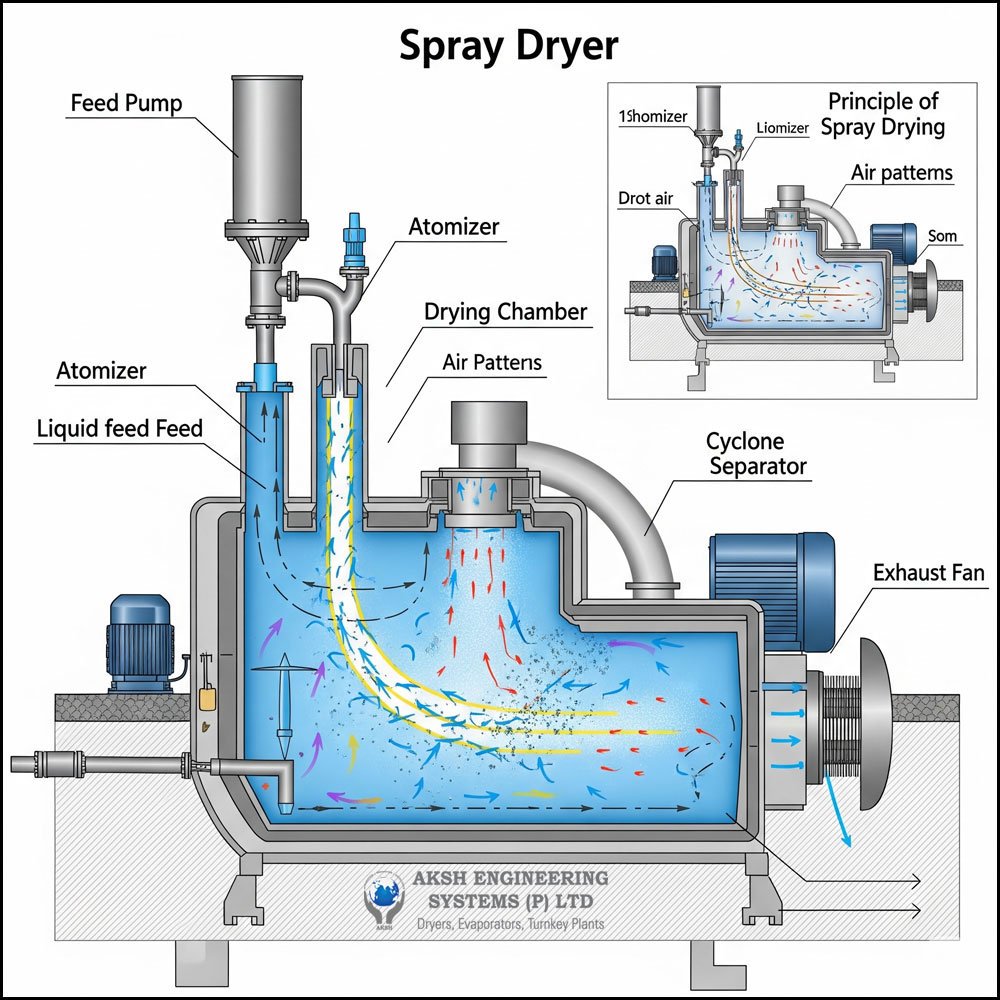

Spray drying is a process that transforms a liquid feed into a dry powder. This is achieved by spraying the liquid into a hot and/or dehumidified drying medium. The drying medium is typically filtered and disinfected atmospheric air, but can also be an inert gas like nitrogen or CO2, depending on the application.

Before drying, the liquid feed is often pre-concentrated through evaporation to efficiently reduce its water content. This concentrated liquid is then introduced as a fine spray or mist into a drying tower or chamber filled with heated air. As the tiny droplets make intimate contact with the hot air, their moisture rapidly evaporates, transforming them into small, dry particles that collect at the bottom of the tower for removal. A key advantage of spray drying is its low heat and short processing time, which helps preserve product quality.

Closed-Loop Spray Dryers: Safety and Efficiency

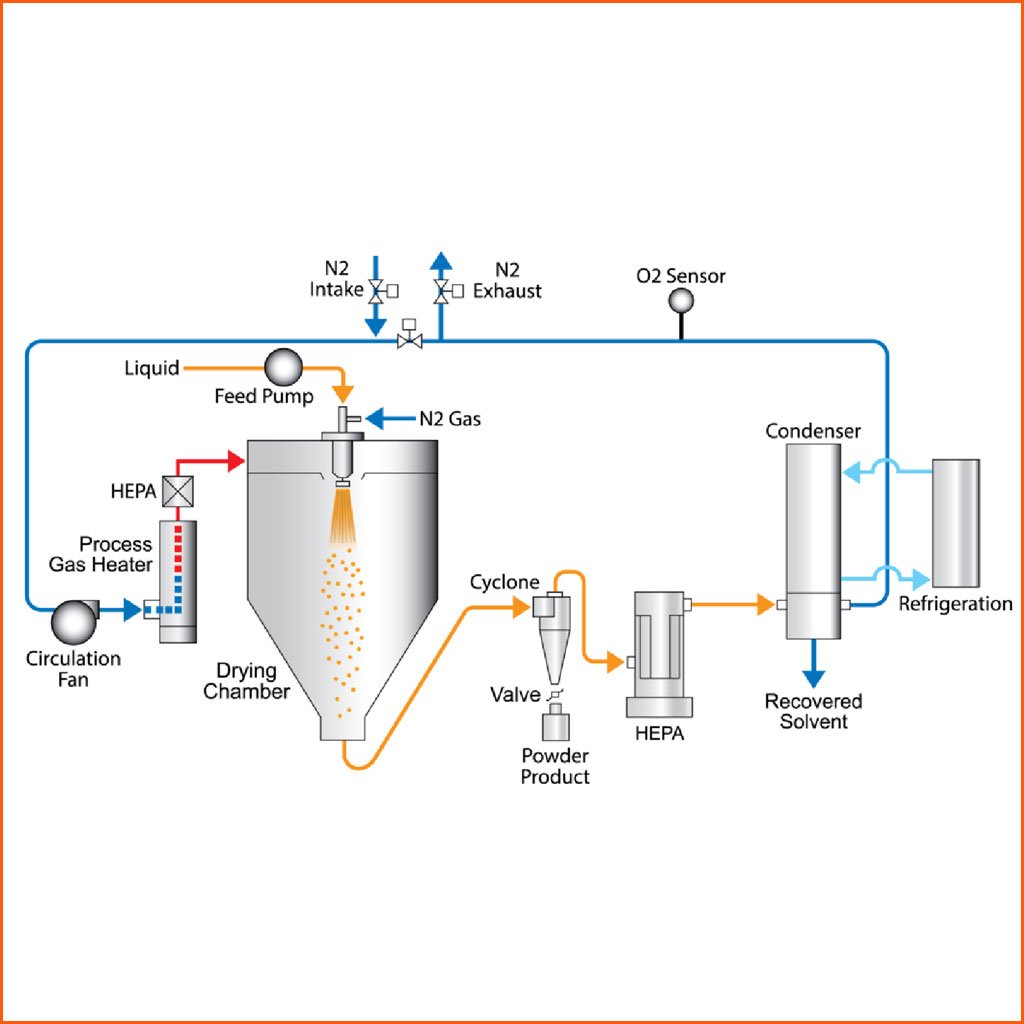

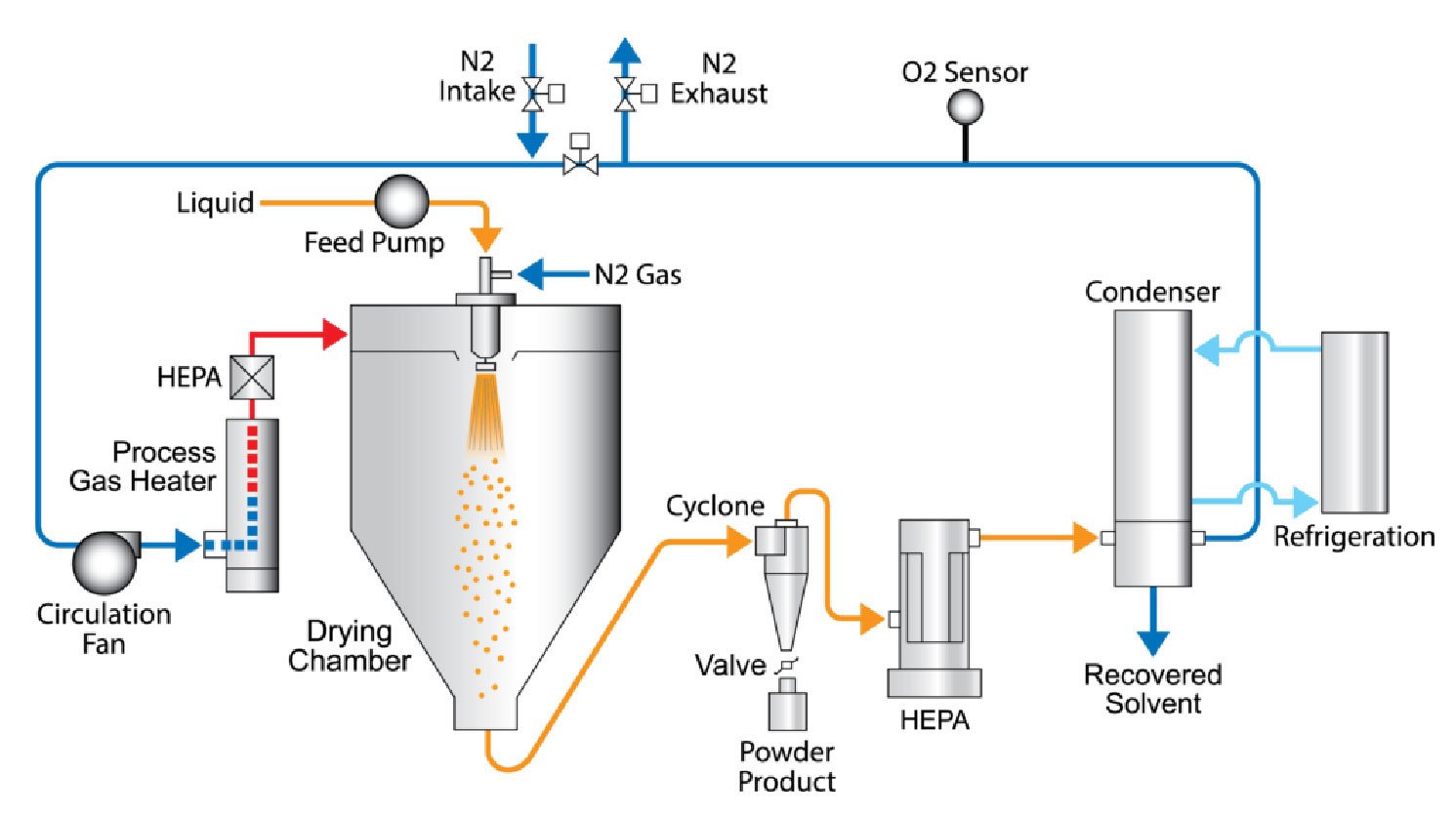

A closed-loop spray dryer operates in an enclosed environment, circulating an inert gas—most commonly nitrogen—as the drying medium. This system is crucial for drying materials that are challenging or hazardous to process with atmospheric air.

Closed-loop spray drying systems are primarily used for:

- Materials containing flammable solvents: This includes alcohol or other combustible organic solvents, eliminating the risk of fire or explosion.

- Products suspended or dissolved in organic solvents: Ensuring safe and efficient drying.

- Oxygen-sensitive materials: Protecting products that can be easily oxidized by contact with air.

- Heat-sensitive products: Ideal for delicate materials like pharmaceuticals and food ingredients, as the inert atmosphere can be controlled more precisely.

- Advanced pharmaceutical applications: Such as the preparation of solid dispersions for solubility enhancement of APIs (Active Pharmaceutical Ingredients) and bulk drugs.

- Encapsulation processes: Providing a controlled environment for effective encapsulation.

Our Closed-Loop Spray Dryer Solutions

We offer a comprehensive range of spray dryers capable of operating in a closed-loop configuration, ensuring safety, environmental protection, and 100% solvent recovery. Our available types include:

- Rotary Atomization Type Spray Drying Plants

- High-Pressure Atomization Type Spray Drying Plants

- Two-Fluid Nozzle Atomization Type Spray Drying Plants

- Combination of Hydraulic and Pneumatic Pressure Nozzles Type Spray Drying Plants

This closed-loop design is particularly vital when spray drying products dissolved in organic solvents, as using atmospheric air would pose a significant risk of explosion or fire. By utilizing an inert gas like nitrogen, these risks are effectively eliminated.

Furthermore, for environmental protection, our closed-cycle systems recover organic solvents in a condenser unit. These units are fed with chilled water and/or brine, depending on the solvent being recovered. This same setup is also beneficial when preventing the oxidative degradation of sensitive products is critical.

Our closed-cycle spray dryers are available for all capacity requirements and can even be used for products suspended or dissolved in water (water-based feeds), offering versatile processing capabilities.

Key Features of Our Closed-Loop Spray Dryers

Our closed-circulation/loop spray dryers offer advanced features designed for efficiency, safety, and compliance:

- Enhanced Drug Solubility: Facilitates the manufacturing of solid dispersions using organic solvent-based spray drying, a technology critical for improving the absorption of poorly soluble drugs. With a significant increase in poorly soluble New Chemical Entities (NCEs), organic solvent spray drying is gaining prominence as a method to enhance solubility.

- 100% Solvent Recovery: Maximizes efficiency and minimizes waste by fully recovering solvents.

- Complete Oxygen Control: Ensures an inert atmosphere, crucial for oxygen-sensitive materials and preventing oxidation.

- Superior Powder Collection: Equipped with cyclones and bag filters for the collection of virtually 100% of powder particles greater than 1 micron in size.

- Advanced Automation: Features full PLC (Programmable Logic Controller) control with SCADA (Supervisory Control and Data Acquisition) for precise operation and monitoring.

- Regulatory Compliance: Adheres to 21 CFR Part 11 guidelines for electronic records and signatures.

- Aseptic and Compliant Design: The complete unit is designed to meet Aseptic GMP (Good Manufacturing Practices) / FLP (Factory Layout Plan) standards, ensuring sterile and compliant operations.

Key Components and Their Functions:

-

Spray Dryer Chamber (Large Conical Vessel): This is the core of the system where the liquid feed is atomized into fine droplets and comes into contact with the hot drying gas.

- Atomizer (Top Center of Chamber): The liquid feed (red arrow) is introduced and atomized, typically using a nozzle or a rotary atomizer, into a fine spray.

- Hot Gas Inlet (Top Right of Chamber, Red Arrow): Hot drying gas enters the chamber to provide the heat for evaporation.

- Product Outlet (Bottom of Chamber, Orange Arrow): The dried powder, in solid particle form, collects at the bottom of the chamber.

- Inert Gas Supply (Top Left, Blue Arrows): This represents the supply of inert gas (e.g., nitrogen) to maintain a non-oxidizing atmosphere within the closed loop. There are control valves to regulate its flow.

- Heater (Left, Vertical Cylinder with Red and Blue Bars): This unit heats the inert drying gas before it enters the spray dryer chamber. The red and blue bars likely indicate the heating mechanism (e.g., electrical heaters or heat exchanger).

- Cyclone Separator (Middle Right, Conical Vessel): After leaving the spray dryer chamber, the gas stream carrying the dried product enters the cyclone. Here, the larger dried particles are separated from the gas stream due to centrifugal forces and fall to the bottom (orange arrow).

- Bag Filter/Filter (Further Right, Rectangular Unit): Following the cyclone, the gas stream passes through a filter (e.g., bag filter or cartridge filter) to remove any remaining fine particles that were not captured by the cyclone, ensuring a clean gas stream for recirculation. The collected fine particles are also part of the product (orange arrow).

- Fan/Blower (Middle Right, Grey Box): This component provides the necessary motive force to circulate the drying gas through the entire closed-loop system.

- Condenser (Far Right, Vertical Cylinders with Blue Arrows): The now moisture-laden inert gas, after passing through the filter, enters the condenser. Here, the evaporated solvent/water is cooled and condensed back into liquid form (dark blue arrow leaving the condenser), separating it from the inert gas. Cooling water (light blue arrows entering and leaving the condenser) circulates to facilitate condensation.

- Inert Gas Return Line (Top, Blue Line): The dried, conditioned inert gas from the condenser is recycled back to the heater, completing the closed loop.

Process Flow Explained:

- Inert Gas Circulation: Inert gas (e.g., nitrogen) is introduced into the system and circulated by the fan.

- Heating: The inert gas passes through the heater, where its temperature is raised to the desired drying temperature.

- Spraying and Drying: The hot inert gas enters the spray dryer chamber. Simultaneously, the liquid feed (containing the product to be dried in a solvent) is atomized into fine droplets within the chamber. The hot gas provides the energy to evaporate the solvent from the droplets, leaving behind dried solid particles.

- Product Collection (Primary): The dried particles, along with the now cooler and solvent-laden inert gas, exit the spray dryer chamber. The larger particles settle at the bottom of the chamber and are collected as the primary product.

- Particle Separation (Secondary): The gas stream carrying entrained fine particles then enters the cyclone separator, where most of the remaining particles are separated and collected.

- Fine Particle Removal: Any very fine particles still present in the gas stream are removed by the subsequent filter. The collected particles from the cyclone and filter are combined with the primary product.

- Solvent Condensation: The clean, solvent-laden inert gas then moves to the condenser. Here, the solvent vapor is condensed back into liquid form by cooling, separating it from the inert gas. The condensed solvent can be collected or disposed of.

- Gas Recycling: The now dry and clean inert gas is recycled back to the heater, completing the closed loop. Make-up inert gas is added as needed to compensate for any minor losses.

Advantages of a Closed-Loop System:

- Safety: Ideal for handling flammable or explosive solvents as oxygen is excluded.

- Environmental Protection: Prevents the release of hazardous or volatile organic compounds (VOCs) into the atmosphere.

- Product Quality: Protects oxygen-sensitive products from degradation.

- Solvent Recovery: Allows for the recovery and reuse of valuable solvents.

- Efficiency: Recirculation of the drying gas can lead to energy savings in some cases, especially if solvent recovery is valuable.

Get in touch

Get in touch with AKSH Engineering for all your industrial drying and evaporation needs. Call us today.