Welcome to our AKSH Engineering

Industrial Spray Dryer Manufacturers by Aksh Engineering, Ahmedabad, Gujarat: Precision Drying for Diverse Industrial Applications

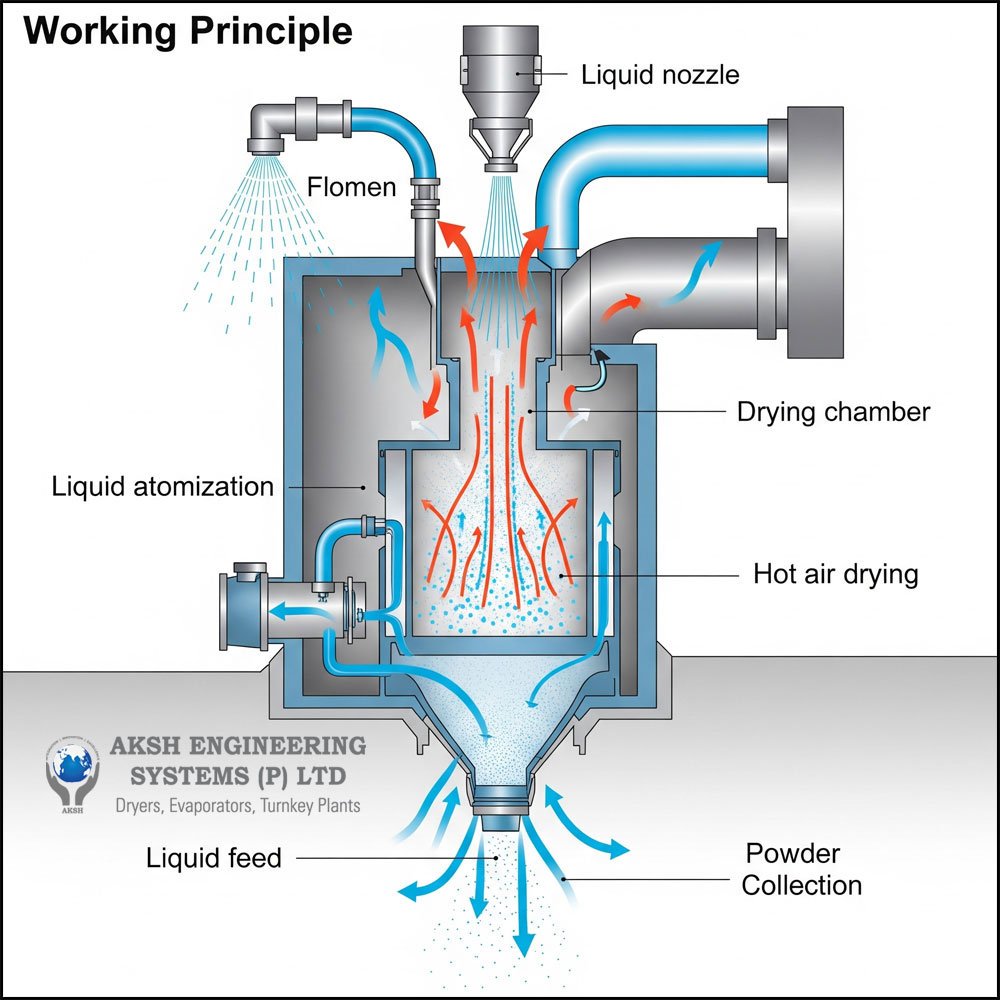

Aksh Engineering Systems Pvt Ltd is a premier spray dryer manufacturer in India, engineering plants that consistently meet the most demanding industrial applications. Our spray dryers efficiently transform liquid substances into dry powder by atomizing the liquid into fine droplets and then rapidly drying them with hot air. The resulting powder is then collected and utilized across various sectors, including food and beverage, pharmaceuticals, ceramics, and other industries.

Spray drying is a process of converting a liquid feed into a dry powder by rapidly atomizing it and bringing it into contact with a hot drying gas. The liquid feed is broken up into small droplets, which are quickly dried by the hot drying gas. The dried particles are then separated from the drying gas and collected. Spray drying is a widely used process in the Drying and Evaporation Systems to the Chemical, Dyestuff, Food, Herbal, Vegetable, Synthetic and Natural Food Color, Herbicides and Fungicides, Sulfur WDG, PPT Silica, Rice Silica, Microcrystalline Cellulose (MCC), Beverage, Pharma Intermediate Chemicals, and Textiles. Extract Natural Products and Pharmaceutical Industry & Alcohol Plants. Aksh will do versatile[ combined Atomizer + Nozzle] process spray dryer for that can be used to produce a wide variety of products, including powdered milk, herbal,coffee, tea, spices, Dyes,OBA, MCC, Mato dextrin D10 to D40 and pharmaceuticals.

Spray Dryers produce dry powder or granules from a liquid pr slurry by rapidly drying it with hot gas. it involves the atomization of a liquid feed into a spray of droplets and contacting the droplets with the hot drying air in a spray drying chamber. The rapid evaporation of moisture from droplets results in formation of dry powder.

The product properties desired by the client are achieved by using the unique and correctly selected atomization systems. Different combinations of products properties like bulk density, product moisture, and dispensary can be achieved during spray drying.

Advantages of Our Spray Dryers

As a leading spray dryer manufacturer, Aksh Engineering's spray dryers offer a multitude of benefits:

Versatile Capacities: We offer spray dryer plants with a broad range of capacities, from small-scale units to commercial-grade systems.

Improved product quality: Spray drying can help to improve the quality of products in a number of ways. For example, it can help to improve the flavor, texture, and nutritional value of food products. Spray drying can also help to improve the solubility and dispersibility of chemicals, making them more effective.

Continuous and Automated Operation: Our spray dryers are built for continuous operation and can be easily integrated into fully automatic control systems.

Product Versatility: Our plants are suitable for both heat-resistant and heat-sensitive products.

Handles Diverse Feed stocks: They can process abrasive, corrosive, flammable, explosive, or toxic feedstocks, provided they are pumpable.

Gentle drying process: Spray drying is a gentle drying process that preserves the quality of the product with required partical size and product moisture.

High efficiency: Spray drying is a very efficient drying process, with evaporation efficiencies of more then 90%.

Extended shelf life: Spray drying can help to extend the shelf life of products by removing moisture. This is especially important for food products, which are susceptible to spoilage.

Reduced transportation and storage costs: Spray drying can help to reduce transportation and storage costs by reducing the weight and volume of products. This is because spray-dried powders are typically much lighter and less bulky than their liquid or slurry counterparts.

Improved product safety: Spray drying can help to improve product safety by removing harmful bacteria and other microorganisms. This is important for food and pharmaceutical products.

Multiple Feedstock Forms: Our spray dryers efficiently process feedstocks in various forms, including solutions, slurries, pastes, gels, suspensions, or melts.

Density Control: The process allows for precise control over the desired product density.

Spherical Particle Production: Our technology can produce nearly spherical particles as required.

Reduced Corrosion Risk: The material being processed does not contact the metal surface until it is dried, significantly reducing the risk of corrosion.

Harnessing Computational Fluid Dynamics (CFD) in Spray Drying

Computational Fluid Dynamics (CFD) technology is increasingly vital in spray drying for process modeling and optimization. CFD simulations help engineers and researchers understand the complex fluid dynamics involved, such as heat and mass transfer, droplet evaporation, and particle formation.

By simulating these processes virtually, we can test different spray drying conditions, optimizing for maximum efficiency and product quality. CFD simulations also help identify potential issues before production begins, allowing for timely adjustments.

Specific applications of CFD in our spray drying processes include:

Modeling Fluid Flow and Heat Transfer: Simulating conditions inside the drying chamber.

Predicting Droplet Behavior: Accurately forecasting droplet size distribution and evaporation rates.

Particle Behavior Simulation: Modeling how different types of particles behave during drying, including agglomeration and breakage.

Optimizing Design: Fine-tuning the spray dryer's design, including nozzle configuration and airflow patterns, for superior performance.

Guaranteed 100% Output Efficiency

Our commitment to continuous innovation and the use of best-in-class technology truly sets us apart as a leading spray dryer manufacturer in India. Spray drying is a complex process with several practical challenges that can arise in industrial settings:

Nozzle Clogging: Blockage of the atomizing nozzle due to solid build-up or impurities can reduce efficiency and lead to uneven particle size.

Product Degradation: High temperatures and extended residence times can degrade products, altering color, flavor, and nutrient content.

Uneven Drying: Non-uniform drying can occur due to inconsistent particle size or poor airflow, resulting in uneven product quality.

Dust Explosion Risk: High concentrations of dry powder in the air can create a dust explosion hazard if ignited.

Equipment Fouling: Accumulation of powder or other material on drying chamber walls or equipment can decrease efficiency and increase maintenance.

Product Sticking: Some products may adhere to drying chamber walls, leading to product loss and reduced efficiency.

High-Grade Materials: We utilize only the highest quality, corrosion-resistant, and food-grade materials (where applicable) in the construction of our spray dryers, ensuring longevity and consistent performance even under demanding operational conditions.

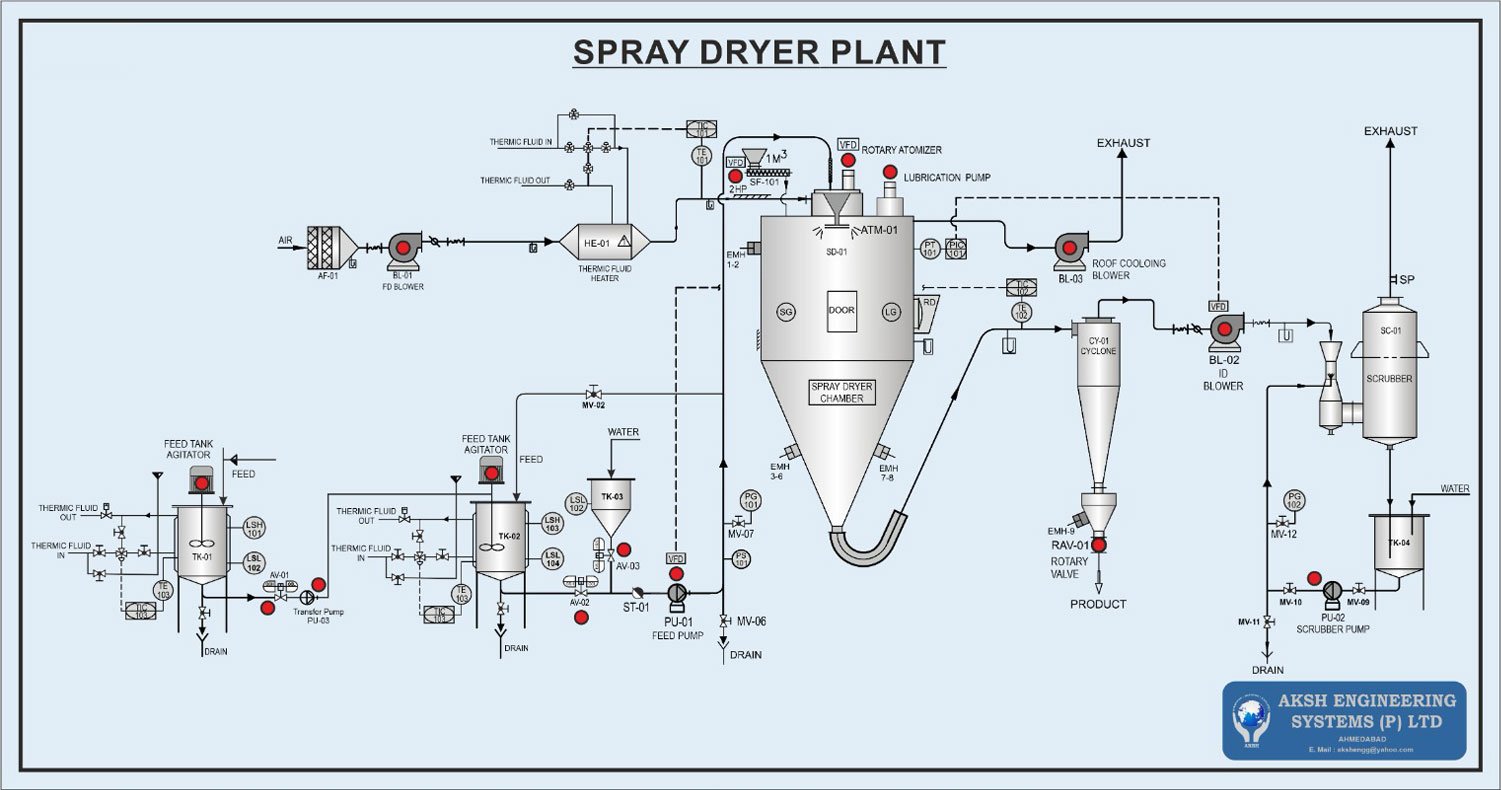

Optimized Design for Minimal Losses: Every component, from the feed pump to the collection system, is meticulously designed to minimize material losses, product sticking, and energy wastage, thereby maximizing the yield.

Stringent Quality Control: Each plant undergoes rigorous multi-stage quality checks and factory acceptance tests (FAT) before dispatch, ensuring that it meets our exacting standards and is ready for peak performance upon installation.

Smart Control Systems: Our spray dryers are equipped with sophisticated PLC/DCS-based control systems that offer real-time monitoring and precise control over all critical process parameters (temperature, airflow, feed rate, atomization pressure). This minimizes human error and ensures stable, optimal operating conditions.

Adaptive Algorithms: Integrated algorithms allow the system to adapt to minor fluctuations in feed characteristics, maintaining consistent drying conditions and preventing product degradation or loss.

Fault Detection & Diagnostics: Our systems incorporate advanced sensors and diagnostic tools that can quickly identify and alert operators to potential issues like nozzle clogging or uneven drying, allowing for immediate corrective action and preventing significant downtime or product loss.

Anti-Clogging Nozzle Technology: We employ specialized nozzle designs and intelligent flushing mechanisms to prevent clogging, ensuring uniform atomization and particle size distribution for consistent drying.

Optimized Airflow Dynamics (CFD-Driven): Leveraging CFD simulations, we design drying chambers with optimized airflow patterns that ensure uniform heat and mass transfer, preventing uneven drying and hotspots that can lead to product degradation. This also minimizes the risk of dust accumulation and potential explosion hazards.

Efficient Product Collection Systems: Our multi-stage collection systems (cyclones, bag filters, etc.) are designed for maximum recovery of the dried powder, significantly reducing product losses typically associated with fine particle escapement.

Non-Stick Chamber Linings: For challenging products prone to sticking, we can incorporate specialized non-stick coatings or designs that facilitate easy product release and minimize material build-up on chamber walls, ensuring continuous operation and higher yield.

Expert Commissioning: Our experienced engineers provide thorough commissioning and startup support, ensuring that the plant is optimally tuned for your specific product and operational requirements.

Operator Training: We provide comprehensive training to your operating and maintenance personnel, empowering them to run the plant efficiently, identify and address minor issues, and maintain peak performance.

Proactive Maintenance Guidance: We offer guidance on preventative maintenance schedules and best practices, extending the lifespan of the equipment and ensuring sustained high output efficiency.

Responsive Technical Support: Our dedicated technical support team is readily available to address any queries or issues that may arise, ensuring minimal disruption to your production.

Our spray dryer plants are meticulously designed to address all these practical problems, guaranteeing 100% output efficiency. Our industry-focused approach, customer-first mindset, and philosophy of partnering with our clients solidify our position as a leading spray dryer manufacturer in India.

Diverse Applications of Spray Dryers

Spray dryers have extensive applications across various industries:

Food and Beverage Processing: Spray drying is one of the most common applications of spray drying. It is used to produce a wide range of food products in powder form, such as milk powder, Way powder ,cheese, Banana , Coconut powder, Orange fruit powder ,coffee powder, and instant soup mixes. Spray drying helps to preserve the flavor, nutrients, and texture of these foods.

Pharmaceutical Production: Essential for producing dry powders from liquid medications, enhancing stability, extending shelf life, and simplifying transport and storage.

Chemicals and Materials: Used to create powders from a wide range of materials, including pigments, polymers, and ceramics, which serve as raw materials in various manufacturing processes.

Environmental Applications: Employed to produce powders from waste streams, such as industrial sludge, enabling safe disposal or reuse.

Nutraceuticals: Utilized to produce powders from natural extracts (e.g., herbal extracts, antioxidants) for nutraceuticals and dietary supplements.

Dyestuff and Auxiliaries: Spray drying is used to produce powdered dyes for use in textiles, plastics, and other materials. The process allows for precise control of the particle size and distribution of the dye, which results in improved performance and consistency.

Starch and derivatives: Spray drying is used to produce a variety of starch-based products, such as powdered glucose, dextrose, and modified starches. Spray drying is also used to produce pregelatinized starches, which can be used to make instant foods and beverages.

Ceramic and minerals: Spray drying is used to produce a variety of ceramic and mineral powders, such as alumina, zirconia, and silica. These powders are used in a wide range of applications, including ceramics, refractories, and catalysts.

Natural products: Spray drying is used to produce a variety of natural products in powder form, such as herbal extracts, probiotics, and enzymes. Spray drying helps to preserve the bioactivity of these products and makes them easier to handle and transport.

Foodstuff: Spray drying is one of the most common applications of spray drying. It is used to produce a wide range of food products in powder form, such as milk powder, Way powder ,cheese, Banana , Coconut powder, Orange fruit powder ,coffee powder, and instant soup mixes. Spray drying helps to preserve the flavor, nutrients, and texture of these foods.

Agriculture products: Spray drying is used to produce a variety of agricultural products in powder form, such as animal feed, pesticides, and fertilizers. Spray drying helps to improve the shelf life and handling of these products.

Vegitable and Alcohal: Spray drying is used to produce a wide variety of powdered food and vegetable like tomato, beat, Garlic, Vinegar, Green chilly, Capsicum, Soya, Ledise finger ,products, Pumpkin including powdered milk, coffee, tea, spices, and seasonings.

Pharmaceutical: Spray drying is used to produce a variety of dry powder inhalers (DPIs), as well as other pharmaceutical products, such as antibiotics and vaccines. In haritanat type close loop Spray dryer use in Pharma products.

Overall, spray dryers offer a broad spectrum of applications across numerous industries. Their ability to transform liquids into powders with improved stability and other desirable properties makes them invaluable for product development and manufacturing.

Types Of Spray Drayer

Spray dryers are highly versatile pieces of equipment used across numerous industries to convert liquid feeds into dry powder. While the fundamental principle remains the same – atomizing a liquid into droplets and rapidly drying them with a hot gas – the specific design and configuration of a spray dryer can vary significantly depending on the material properties, desired product characteristics, and operational needs.

Here are the main types of spray dryers, categorized primarily by their atomization method and air-flow patterns:

The method of atomizing the liquid feed into fine droplets is a crucial distinguishing factor, as it directly impacts droplet size distribution, energy consumption, and the types of materials that can be processed.

- Rotary Atomizer Spray Dryers (Centrifugal Atomizers)

- Principle: A high-speed rotating disc, cup, or wheel discharges the liquid feed centrifugally, breaking it into fine droplets. The rotational speed of the atomizer controls the droplet size.

- Advantages:

- High Capacity: Can handle large volumes of liquid feed, suitable for industrial-scale production.

- Versatility: Accommodates a wide range of feed viscosities, including highly viscous liquids, slurries, and pastes, making them flexible for various materials.

- Uniform Particle Size: Generally produces a more uniform and controllable particle size distribution compared to some nozzle types.

- Less Prone to Clogging: The centrifugal action makes them less susceptible to clogging, even with abrasive or high-solids feeds.

- Lower Operating Pressure: Does not require high feed pressures for atomization.

- Common Applications: Dairy products (milk powder), detergents, dyes, ceramics, inorganic chemicals, herbal extracts.

- Pressure Nozzle Spray Dryers (Single-Fluid Nozzles / Hydraulic Nozzles)

- Principle: The liquid feed is pumped at high pressure (hydraulic pressure) through a small orifice in a nozzle. The pressure energy is converted into kinetic energy, causing the liquid to atomize into a fine spray.

- Advantages:

- Fine Particle Production: Can produce very fine powders, especially with high pressures.

- Simplicity: Relatively simple design and operation compared to rotary atomizers.

- Energy Efficiency (for thin liquids): Can be energy efficient for low-viscosity feeds.

- Narrow Particle Size Distribution: Can achieve a relatively narrow particle size distribution for specific applications.

- Disadvantages:

- Prone to Clogging: Smaller orifices are susceptible to clogging, especially with viscous or particulate-laden feeds.

- Limited Viscosity Range: Best suited for low to medium viscosity liquids.

- Wear and Tear: High pressures can cause wear on nozzle orifices, affecting performance over time.

- Common Applications: Coffee, tea, egg powder, pharmaceuticals (e.g., APIs), some food ingredients.

- Two-Fluid Nozzle Spray Dryers (Pneumatic Nozzles / Air Atomizing Nozzles)

- Principle: Two fluids (liquid feed and a high-velocity gas, typically compressed air or steam) meet either internally or externally within the nozzle. The energy from the high-velocity gas breaks up the liquid into fine droplets.

- Advantages:

- Very Fine Droplets: Capable of producing extremely fine droplets and therefore very fine powders, often with average particle sizes below 50µm.

- Adjustable Droplet Size: Droplet size can be precisely controlled by adjusting the gas and liquid flow rates independently.

- Handles Viscous Feeds: Can handle more viscous feeds than single-fluid pressure nozzles, as atomization is aided by the gas.

- Lower Liquid Pressure: Can operate with lower liquid pressures compared to pressure nozzles.

- Disadvantages:

- Higher Energy Consumption: Requires compressed gas, leading to higher operating costs.

- Potential for Gas Contamination: Requires careful consideration of the drying gas if product purity is critical.

- Common Applications: Pilot dryers, pharmaceuticals, fragrances, specialty chemicals, applications requiring very fine powders.

- Ultrasonic Nozzle Spray Dryers

- Principle: Utilizes high-frequency vibrations (ultrasonic waves) to atomize the liquid into extremely uniform and fine droplets. The liquid is fed onto a vibrating surface (e.g., a vibrating horn), which causes it to break into a mist.

- Advantages:

- Extremely Uniform and Fine Droplets: Produces the most uniform and finest droplets among all atomization methods.

- Low Velocity Spray: The droplets are formed at low velocity, which is gentle for delicate or heat-sensitive materials.

- Non-Clogging: Highly resistant to clogging due to the large orifices.

- Disadvantages:

- Lower Capacity: Typically used for smaller scale production or specialized applications.

- Higher Capital Cost: Can be more expensive than other atomization methods.

- Common Applications: Pharmaceuticals, advanced materials, microencapsulation, research and development.

The way hot air interacts with the atomized spray within the drying chamber significantly impacts drying efficiency, product properties, and suitability for heat-sensitive materials.

- Co-Current Flow Spray Dryers

- Principle: Both the hot drying air and the atomized liquid spray enter the drying chamber from the same end (usually the top) and flow in the same direction.

- Advantages:

- Ideal for Heat-Sensitive Materials: The atomized droplets immediately encounter the hottest air, but simultaneous rapid evaporation quickly cools the air around the droplets, minimizing heat exposure to the drying product. This keeps the particle temperature low.

- Greater Control over Product Temperature: Easier to control the temperature of the dried product.

- Good for Fine Powders: Promotes rapid initial drying and fine particle formation.

- Disadvantages: Slightly less thermally efficient than counter-current for some materials due to higher exhaust temperatures.

- Common Applications: Dairy products, food ingredients, pharmaceuticals, enzymes, many common spray drying applications.

- Counter-Current Flow Spray Dryers

- Principle: The hot drying air enters the drying chamber from the bottom, while the atomized liquid spray enters from the top. The air and droplets flow in opposite directions.

- Advantages:

- Higher Thermal Efficiency: The driest particles come into contact with the hottest air at the bottom, maximizing heat transfer and resulting in lower exhaust gas temperatures.

- Suitable for Non-Heat Sensitive Materials: Ideal for materials that can withstand higher temperatures without degradation.

- o Disadvantages:

- Not suitable for highly heat-sensitive products, as the almost dry particles are exposed to the hottest air.

- Can lead to increased wall sticking for some materials.

- Common Applications: Inorganic chemicals, pigments, soaps, detergents, ceramics, certain minerals.

- Mixed Flow Spray Dryers

- Principle: This configuration combines aspects of both co-current and counter-current flows. Hot air might enter tangentially or from a specific point, while the atomizer is placed to create a mixed flow pattern (e.g., atomizer at the bottom, hot air from the top flowing downwards, creating a "fountain" effect).

- Advantages:

- Offers a balance of thermal efficiency and product quality.

- Can achieve specific product properties or particle morphologies.

- Can be more energy-efficient than pure co-current for certain materials.

- Common Applications: Specialized applications where specific particle characteristics (e.g., larger particles, agglomerates) or a balance of efficiency and heat sensitivity is desired.

- Single-Stage Spray Dryers

- Principle: The entire drying process, from liquid atomization to final powder collection, occurs within a single drying chamber.

- Best for: Materials where the desired final moisture content can be achieved in one step and a specific particle size/morphology is not critical to achieve agglomeration.

- Multi-Stage Spray Dryers (e.g., Two-Stage, Three-Stage)

- Principle: These systems combine the spray drying chamber with additional drying stages, most commonly integrated or external fluidized beds.

- First Stage (Spray Dryer): Reduces moisture content from liquid to a lower, but often still higher than desired, level. Second Stage (Fluidized Bed):

- Second Stage (Fluidized Bed): Further dries and/or cools the powder, often promoting agglomeration, reducing fines, and achieving precise moisture control.

- Advantages:

- Improved Energy Efficiency: Heat from the exhaust air of the spray dryer can be used in the fluidized bed.

- Enhanced Product Quality: Can produce dust-free, agglomerated, and highly soluble powders with precise moisture control.

- Higher Bulk Density: Agglomeration can increase bulk density.

- Reduced Fines: Minimizes dust formation and loss.

- Common Applications: Instant coffee, milk powder, pharmaceuticals requiring excellent solubility, food ingredients that need to be free-flowing or easily dispersible.

- Principle: These systems combine the spray drying chamber with additional drying stages, most commonly integrated or external fluidized beds.

- Closed-Loop Spray Dryers (Closed Cycle / Inert Gas Dryers)

- Principle: Instead of air, an inert gas (like nitrogen) is used as the drying medium and is continuously recycled. After drying, the solvent is condensed out, and the inert gas is reheated and returned to the drying chamber.

- Advantages:

- Safety: Essential for drying flammable, explosive, or toxic solvents.

- Environmental Compliance: Prevents emission of hazardous solvents into the atmosphere.

- Solvent Recovery: Allows for efficient recovery of valuable solvents.

- Product Purity: Prevents oxidation or degradation of oxygen-sensitive products.

- Disadvantages:

- Higher capital cost due to the need for a condenser, inert gas supply, and sealing.

- Common Applications: Pharmaceuticals, specialty chemicals, fine chemicals, materials with organic solvents.

- Semi-Closed Loop Spray Dryers

- Principle: A hybrid system where some portion of the drying gas is recycled, often to improve thermal efficiency or to handle certain hazardous components, but not fully sealed like a closed loop.

The choice of spray dryer type is a complex decision that requires careful consideration of the feed material's characteristics, desired powder properties (particle size, morphology, bulk density, moisture content), energy costs, safety requirements, and overall production capacity. Expert spray dryer manufacturers often conduct pilot plant trials to determine the optimal configuration for a specific application.

Get in touch

Get in touch with AKSH Engineering for all your industrial drying and evaporation needs. Call us today.